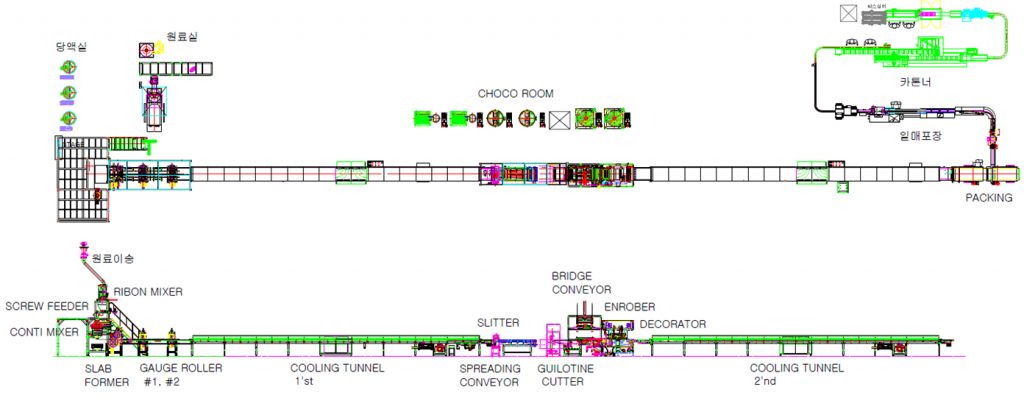

Cereal bar production line

We started with factory production automation and now we have a lot of experience and technology, We are doing our best to supply equipment that can contribute to productivity and quality improvement that customers want.

Product

It is the equipment for manufacturing cereal bars, grain bars, energy bars, organic grain bars, etc. and it can perform chocolate coating, semi-coating and whole coating. Also, equipment that produces products available for decorations are manufactured.

| CAPACITY | 20column X 15rpm (max) |

|---|---|

| CooKIE SIZE | W : 30mm ~ 32mm, L : 80mm ~ 120mm, H : 12mm ~ 15mm |

Introduction of manufacturing facilities

Ingredient supply device

Ingredient supply system including sugar solution preparation tank system, flavor supply device, cereal and grain ingredient roasting device, ingredient transfer device, chocolate ingredient supply device, etc.

Previous

Next

Previous

Next

Automatic ingredient pnewmatic transfer device

Ribon mixer, Screw feeder, Conti mixer

Molding roller and chocolate chip supply device

It uses roller to spread out the mixed ingredient dough evenly at consistent thickness and chocolate chip addition process can be added.

Previous

Next

1st cooling tunnel

It goes through the process of cooling the molded product through cooling tunnel

Slitter, Guillotine cutter

It is the process of cutting the ingredient that passed through 1st cooling tunnel in desired size horizontally and vertically

Previous

Next

Previous

Next

Enrober & Decorator

With chocolate coating machine and decorator machine installed, chocolate coating and decoration can be applied to products

2nd cooling tunnel

Products that went through molding and coating are cooled down through 2nd cooling tunnel and are made into condition for packing

Previous

Next

Previous

Next

PACKING

Automatic packing machine and automatic labeler are used to finalize the internal and external packing to standby for release

food & bio plant, automation

We take responsibility and effort to satisfy users

All Utech employees are veterans who have worked in automation sector for decades.

Also, we have established a corporation in Shenyang in China to enter the Chinese market, and doing export to Vietnam, Pakistan and Russia.

CEO Lee dong deok

TOP