Raw Handling System

We started with factory production automation, and now we have many experiences and technologies, and we are doing our best to supply equipments which can contribute to productivity improvement and quality improvement that our customers want.

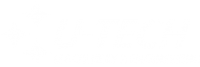

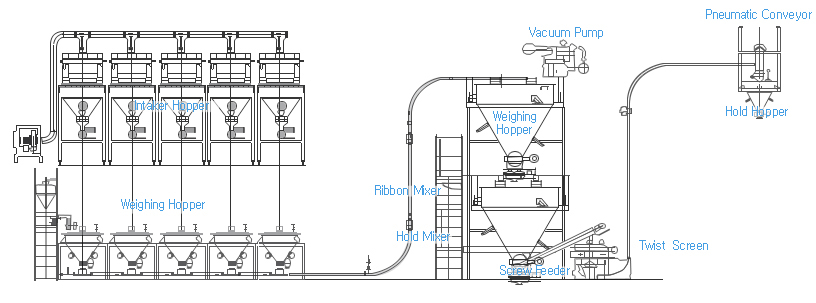

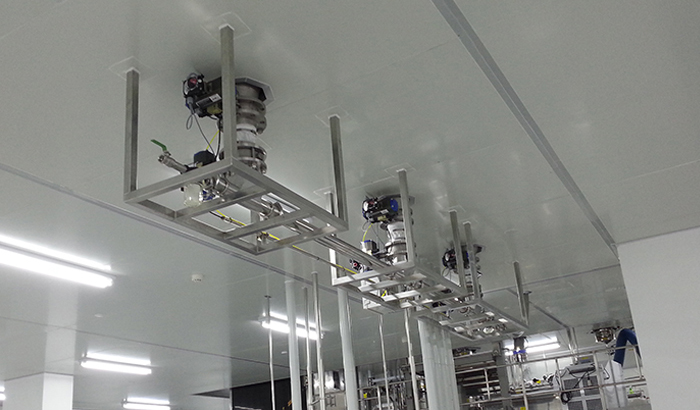

The newmatic conveyor is a device that transports the powder material by using the flow energy due to the pressure difference of the gas.

The newmatic conveyor consists of a material provider (raw material injection hopper), a transfer pipe (raw material transfer pipe), an air motor (vacuum pump), and a material / air separator (filter unit) etc.

If the pressure at the position where the material is fed to the transfer pipe is higher than the atmospheric pressure, it can be classified into a pressurizing type, if it is low, it can be classified as a vacuum or vacuum suction type newmatic conveyor.

Vacuum suction method of powder conveying device is a method of transferring the powder by suction of air. When the powder and air flow into the conveyor, the air and powder are separated by the air filter unit and the powder is loaded inside. The loaded powder is passed through the raw material weighing screw, weighed, and then correct quantity is supplied to the blender.

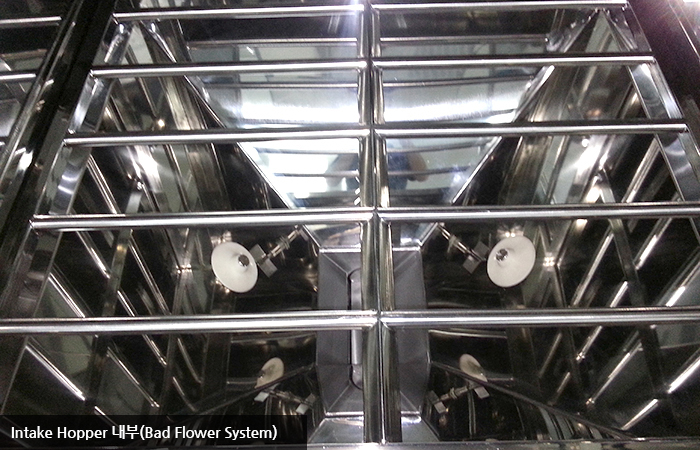

SUPPLY INTAKE HOPPER

Transfer LINE

U-TECH’s newmatic conveyor complements the disadvantages and limitations of the vacuum pump-type BATCH method using compressed air of PIAB and uses medium density continuous type which combines PIAB’s excellent filter and automatic cleaning function. Particularly when a large amount is to be transferred in a short time, and when cleaning is required, it is easy to disassemble by anyone, and time and effort can be shortened.

| Type | Medium density continuous type (U-TECH + PIAB) | Medium density BATCH type (PIAB) |

|---|---|---|

| Facility maintenance cost | Very low | Very low |

| Driving costs | low | low |

| Air volume during transport | 20% ~40% | 30% ~ 50% |

| Driving noise | Slightly high | Slightly high |

| Damage of conveyed product | very small | small |

| Facility scale (filter) | small | small |

| Efficiency of raw material transfer | Highness | Low (BATCH type exhaust) |

| Pipe clogging | almost none | have clogging (when vertical section is long) |

| Decreased efficiency due to filter clogging | almost none | low |

| Form of hopper | Cyclone | Filter & small cyclone section |

| Air motor | Vacuum suction only ring blower | Vacuum pump (compressed air) |

| Cleaning | easy | easy |

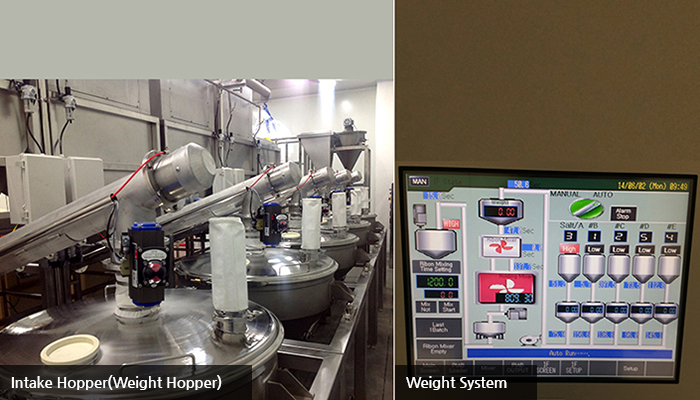

Weighing Hopper

Automatically implements precise powder weighing by putting a certain amount of powder of storage material according

to time and process without error

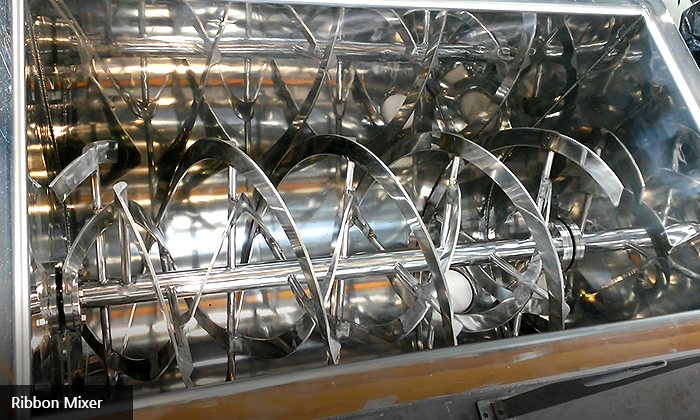

Mix Ribbon Mixer

Inside the SHELL, there is a ribbon-shaped agitator that moves and mixes materials in three-dimensional motion: vertical, horizontal and rotational.

Two ribbons with different movement directions of powder are crossed and one of the pitches is large and normally the ribbons on the inner side are made smaller in pitch, and when the same rotation is sent, the blend of the pest is able to obtain a mixing result that is not seen in other kinds due to the complex flow and contrary upward and downward movement by the ribbons.

Various tanks – Optimal raw material mixing / storage tank designed to meet the requirements for production of various product.

Mixing Tank

Magnetic Mixer

– There is no precipitation phenomenon because of excellent agitation force.

– No additional equipment required for drive unit

– It is easy to clean because there is no shaft.

– Semi-permanent life

– Even if there is a problem with the motor, it can be processed without moving the liquid.

Agitator Mixer

– Mixing of the vortex flow concentrically around the stirring wing

Weighting System

Mixing & Weight System

Air service tank & mixing water storage tank

Hot water production tank

60% storage in molten lower cone in Grills (80 °C) solid shortening