Packing

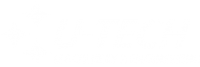

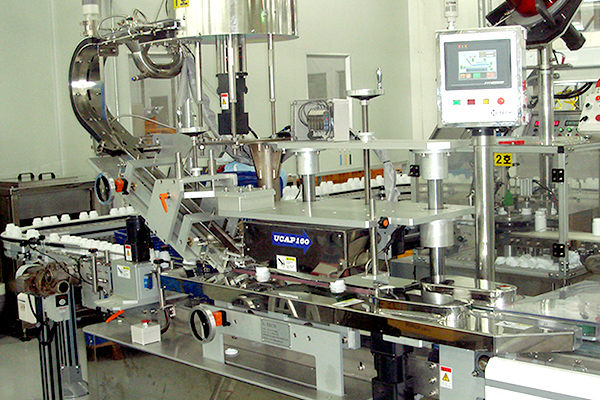

Multipacking Machine

- Effective equipment to solve several processes in one equipment due to narrow installation site and lack of personnel

- When product container is put in, silica gel automatic feeding, cap feeding, and capping work are carried out sequentially and multi-packing work is completed.

Previous

Next

| Processing capacity | MAX 120ea/min (Processing capacity may vary depending on product shape and size) |

|---|---|

| Processing bottle size | Diameter 30 ~ 100mm Height 40 ~ 200mm |

| Control | PC & TOUCH / PLC & TOUCH |

| Installation area | may vary according to the order specification |

| Applicable product | BOTTLE |

Weight checker

- Effective equipment to solve several processes in one equipment for reasons such as small installation place and shortage of personnel.

- When the weight differs from the reference weight, the product is sorted by moving different direction with the normal product

- Automatically weighs the weight by selecting it and contributes to productivity improvement

Previous

Next

| Processing capacity | MAX 120ea/min (Processing capacity may vary depending on product shape and size) |

|---|---|

| Processing box size | Width 200 ~ 550mm Length 200 ~ 600mm |

| Control | PLC |

| Installation area | 850W X 1700L X 1400H |

| Processing bottle size | 200g ~ 10Kg |

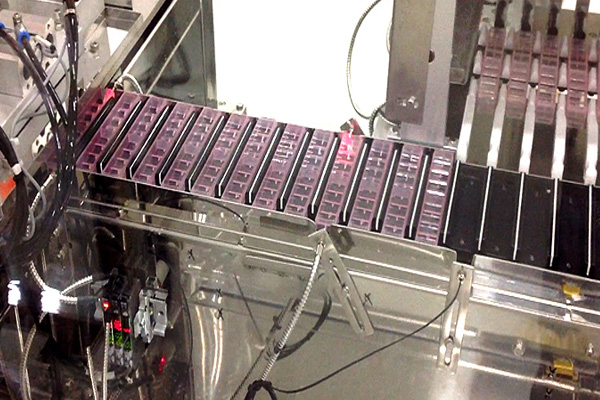

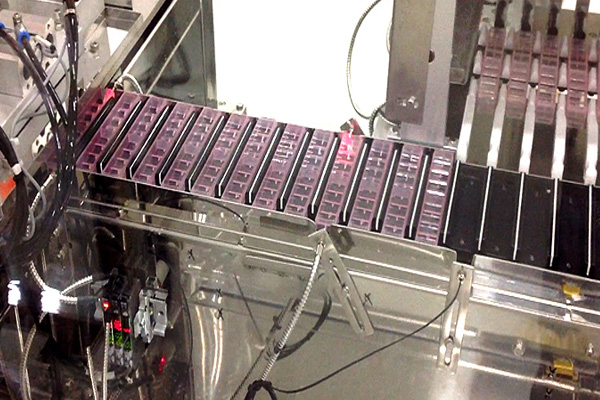

Case Packing Machine

- Effective equipment to solve several processes in one equipment for reasons such as small installation place and shortage of personnel.

Previous

Next

| Processing capacity | MAX. 100 ea/min (Processing capacity may vary depending on product shape and size) |

|---|---|

| Control | PLC & TOUCH / PLC & TOUCH |

| Installation area | Different according to specification specifications |

| Applicable product | Gum, Candy, Chocolate, ball case package |

| Processing process | Case supply → Insert the product → Inspection → Lid assembly → Discharge → Alignment (additional process: inspection, printing) |

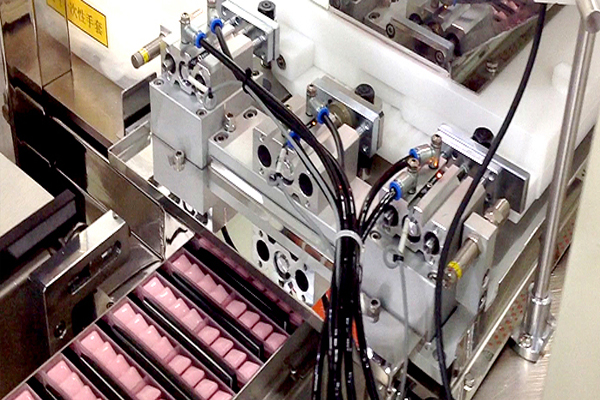

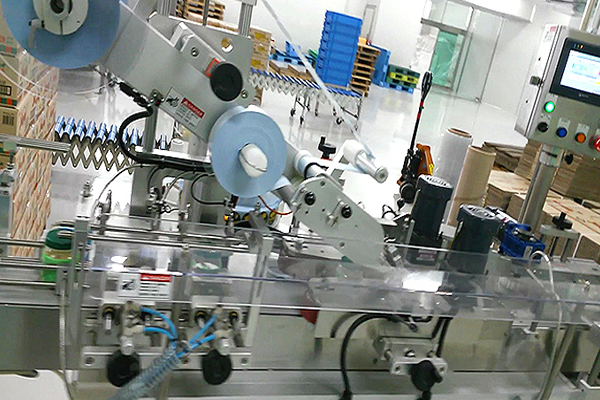

Box Labeler

- Effective equipment to solve several processes in one equipment for reasons such as small installation place and shortage of personnel.

- Introduced by many companies with accuracy, time efficiency and shortening

- Outputs and sticker attachment for fast processing

Previous

Next

| Processing capacity | MAX 80ea/min (Processing capacity may vary depending on product shape and size) |

|---|---|

| Control | PLC & TOUCH |

| Installation area | 1500W X 3000L X 1600H |

| Applicable product | Compact box packaging |

| Additional process | Inspection, Printing |

Case Packing Machine

- Effective equipment to solve several processes in one equipment for reasons such as small installation place and shortage of personnel.

Previous

Next

| Processing capacity | MAX. 100 ea/min (Processing capacity may vary depending on product shape and size) |

|---|---|

| Control | PLC & TOUCH / PLC & TOUCH |

| Installation area | Different according to specification specifications |

| Applicable product | Gum, Candy, Chocolate, ball case package |

| Processing process | Case supply → Insert the product → Inspection → Lid assembly → Discharge → Alignment (additional process: inspection, printing) |

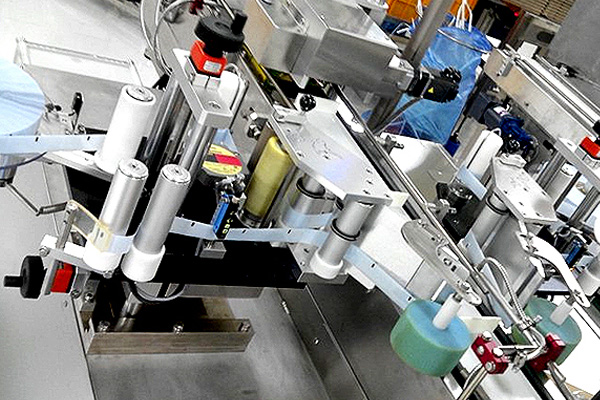

Labeler

- Effective equipment to solve several processes in one equipment for reasons such as small installation place and shortage of personnel.

- Introduced by many companies with accuracy, time efficiency and shortening

- This labeler can be applied to cylinders such as bottles and cans.

- Fast attachment to the correct position without bubbles

Previous

Next

| Processing capacity | MAX. 80 ea/min (Processing capacity may vary depending on product shape and size) |

|---|---|

| Control | PLC & TOUCH / PLC & TOUCH |

| Installation area | 1500W X 3000L X 1600H |

| Processing bottle size | Diameter 30 ~ 100mm Height 40 ~ 200mm (Applicable product : BOTTLE, CAN) |

| Additional process | Inspection, Printing |

Multi Labeler

- one multilabeller can label various sizes of containers

Previous

Next

| capacity | 1,800 ea/Hr (Processing capacity may vary depending on product shape and size) |

|---|---|

| control | PLC & TOUCH Pannel |

| Size | 1100W X 1300L X 1950H |

| Case size | Max Width 300mm, Height 200mm |

| Use | Lunch Box Labeling |

Capping Machine(rotary type)

- Effective equipment to solve several processes in one equipment for reasons such as small installation place and shortage of personnel.

Previous

Next

| Processing capacity | MAX. 80 ea/min (Processing capacity may vary depending on bottle shape, interval, and conveyor speed) |

|---|---|

| Control | PLC & TOUCH |

| Installation area | 800W X 800L X 1600H |

| Processing bottle size | Diameter 60 ~ 100mm Height 40 ~ 200mm |

| Applicable product | Gum, Candy, Chocolate, ball |

Bottle Unscrambler

- Effective equipment to solve several processes in one equipment for reasons such as small installation place and shortage of personnel.

Previous

Next

| Processing capacity | MAX. 120 ea/min & 200ea/min (Processing capacity may vary depending on product shape and size) |

|---|---|

| Control | PLC & TOUCH |

| Installation area | 1500W X 4500L X 2000H |

| Processing bottle size | Diameter 30 ~ 100mm Height 40 ~ 200mm (Applicable product : BOTTLE, CAN) |

| Cleaning method | IONIZER / AR |

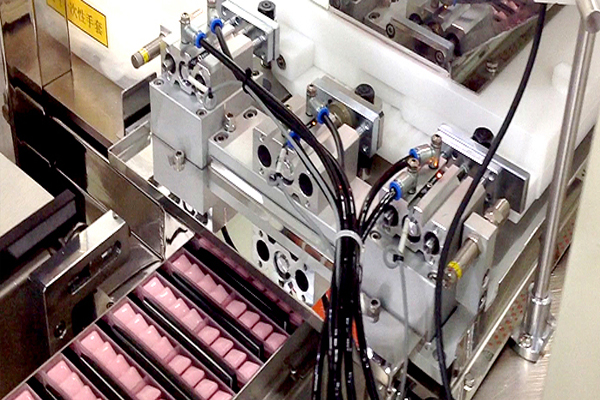

Counter Machine

- Effective equipment to solve several processes in one equipment for reasons such as small installation place and shortage of personnel.

Previous

Next

| Processing capacity | MAX. 2000(Ø10)/min (Processing capacity may vary depending on product shape and size) |

|---|---|

| Control | PC & TOUCH |

| Installation area | 800W X 3500L X 2000H |

| Processing bottle size | Diameter 30 ~ 100mm Height 40 ~ 200mm (Applicable product : BOTTLE, CAN) |

| Gate method | Double shutter |

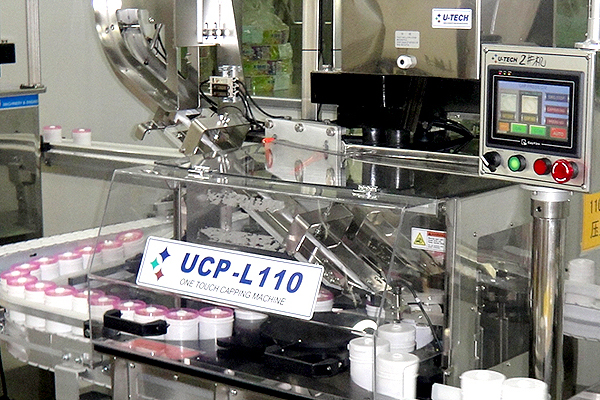

Capping Machine

- Effective equipment to solve several processes in one equipment for reasons such as small installation place and shortage of personnel.

- Adjusted according to the size of the processing container (diameter: 30 to 60 mm, height: 40 to 200 mm)

- Maximize work efficiency by connecting to work line

- Roller rotates and returns the cap

Previous

Next

| Processing capacity | MAX. 120 ea/min (Processing capacity may vary depending on bottle shape, interval, and conveyor speed) |

|---|---|

| Control | PLC & TOUCH |

| Installation area | 800W X 2000L X 1600H |

| Applicable product | Diameter 30 ~ 60mm Height 40 ~ 200mm |

| Applicable product | Gum, Candy, Chocolate |