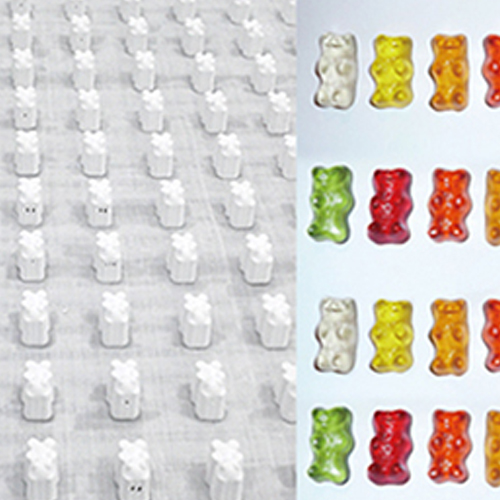

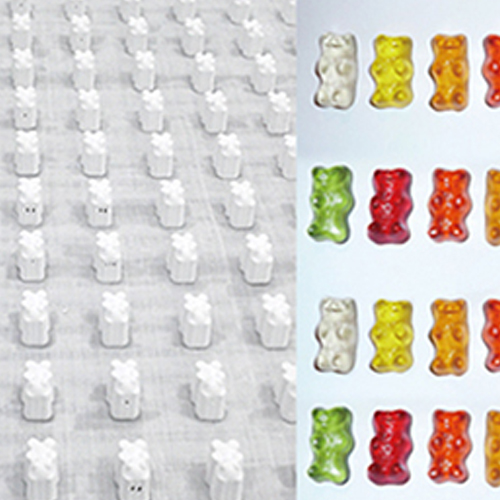

Jelly production line

We started with factory production automation and now we have a lot of experience and technology, We are doing our best to supply equipment that can contribute to productivity and quality improvement that customers want.

Product

Korea’s only jelly production line manufacturer

Can be installed at a price less than 60% of European facilities

Inexpensive compared to China, fast after service and very fast delivery date

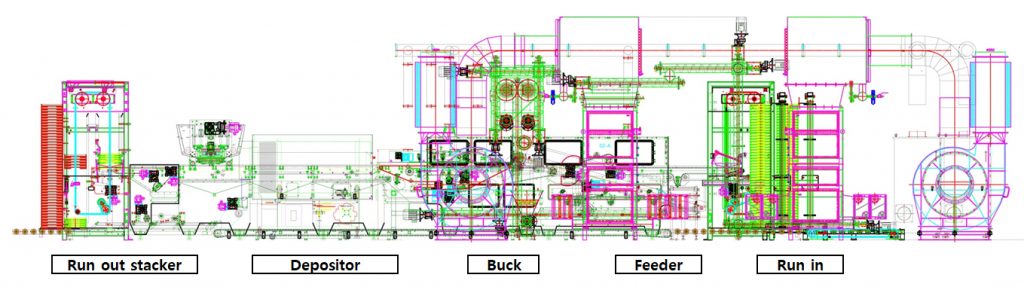

Introduction of manufacturing facilities

♦Specification

| CAPACITY | 600Kg/Hr ~ 1000Kg/Hr, 300Kg/Hr |

|---|---|

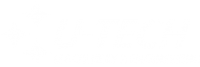

| TYPE | STARCH MOGUL DEPOGITOR – ferment – Exhaust – Coating – Packaging |

| PROCESS | Melt – Concentrate – Form (Starch drying) |

| TYPE |

1) DEPOSITOR – 2COLOR 2SET 2) STARCH MOGUL 3) Starch Recovery Supply, Dry continuous method 4. 24 Hours Ferment |

| CAPACITY | UTJ-300 : 200~300Kg/Hr, UTJ-1000 : 1,000~1,500Kg/Hr |

|---|---|

| PROCESS | Dissolving – Concentrating – Molding (starch drying, Depositing, ferment, exhaust, coating, Packing) |

| TYPE | 1.General Depositor, Center filling type Depositor (Parallel installation possible) 2.A system for drying and cooling by circulating starch 3.Whisk semi-finished starch, Oil and Sugar Coating Systems 4. 24 Hours Ferment |

Production equipment introduction

Weighting / Mixing Tank

Vibration feeder

Starch recirculation

Weighting / Mixing Tank

Mixing Tank

Depositor

In-rack and tray

Depositor

Starch dry and cooling

Mould

Starch Recirculation

Starch dryer

Out –rack & tray

Tumbler

Starch separation machine

전분털기 & Mesh Belt

Starch tray IN

Starch tray OUT

Oil Coating tumbler

Production equipment introduction

Weighting / Mixing Tank

Mixing Tank

Depositor

Mould

Starch Recirculation

Starch dryer

Seasoning mesh belt

Starch tray IN

Starch tray OUT